Pouring a Slab Foundation for a Carport or Garage

The Ideal Slab for a Standard Building

At Coast to Coast Carports, we are frequently asked how to pour foundations or slabs, even though we do not do so. Usually, it is for one of our metal buildings, so we do our best to guide our clients to get the finish that they need. We always recommend that anyone hire a certified contractor specializing in slabs or foundations and order Site-Specific Engineered Drawing for the contractor to use as a guide. However, if you are confident and want to complete the slab for yourself, then the following information may come in handy. Bear in mind that this is not an instruction manual. This article will give you a few tips assuming you already know the basics or if you have hired someone to do the actual labor.

Legal Stuff

Before you break ground or order any steel building, you may need to check with your local authorities for the building codes. You may need to obtain a permit for the upcoming structure. If you do not need a permit, you can probably skip this section. Usually, you can call your city or county courthouse, and they will direct you from there. They will tell you what their regulations are for a building and/or a slab or foundation. These codes may not be the same for everyone in one county or even for everyone in one city. Areas with major elevation differences set the codes based on actual addresses. Building codes will usually tell you that your footers (the outermost part of a slab usually supporting the weight of a structure) need to be set below the frost depth (usually over 18″ but is set by the local municipality). The codes will also set a required wind load, snow load, and live load requirements. Wind loads are usually defined as a 3-second wind gust that a structure should be able to withstand without taking damage (90 mph used to be a standard, but many municipalities are increasing requirements). Snow loads are usually referred to as “ground snow loads” and usually measured in pounds per square foot (lb. per sq/ft). A rule of thumb is everyone gets 20 lb. If your area gets more snow than most, you probably will need to make sure your metal building is built to withstand more. Live loads describe the weight of a "live" person on the building. These are usually measured in the same way as snow loads.

"How do I prove that my building will meet the local wind, snow, and live loads?"

A set of site-specific engineered drawings will include specs on the materials in which the building will be made of, how they will be put together, how it will be attached to the foundation or ground, and how the foundation needs to be built. The engineered drawings will have a state-licensed engineer's stamp of approval. This will tell the building inspector and the permitting office that your building is up to code. Of course, the building needs to be built according to the drawings.

"How do I get a set of Drawings?"

The easiest way is to ask the company that you're buying your building from for information. Most metal building companies will offer "certified buildings." These are buildings that are pre-engineered for certain wind, snow, and live loads and come with "generic drawings." In many cases, these generic drawings will be enough to get a permit and pass inspection. Your local municipality will let you know if it will be enough before you have to pay anything to anyone. If the generics are not enough, the building company you are dealing with will probably act as the middleman for you and assist you in getting your site-specific drawings. You will have a set mailed to you. Then you will need to take those to get any required permits before the metal building installation starts. If you're doing everything yourself, then you will need to contact a state licensed engineer to do your drawings.

Picking a type of Slab or Foundation

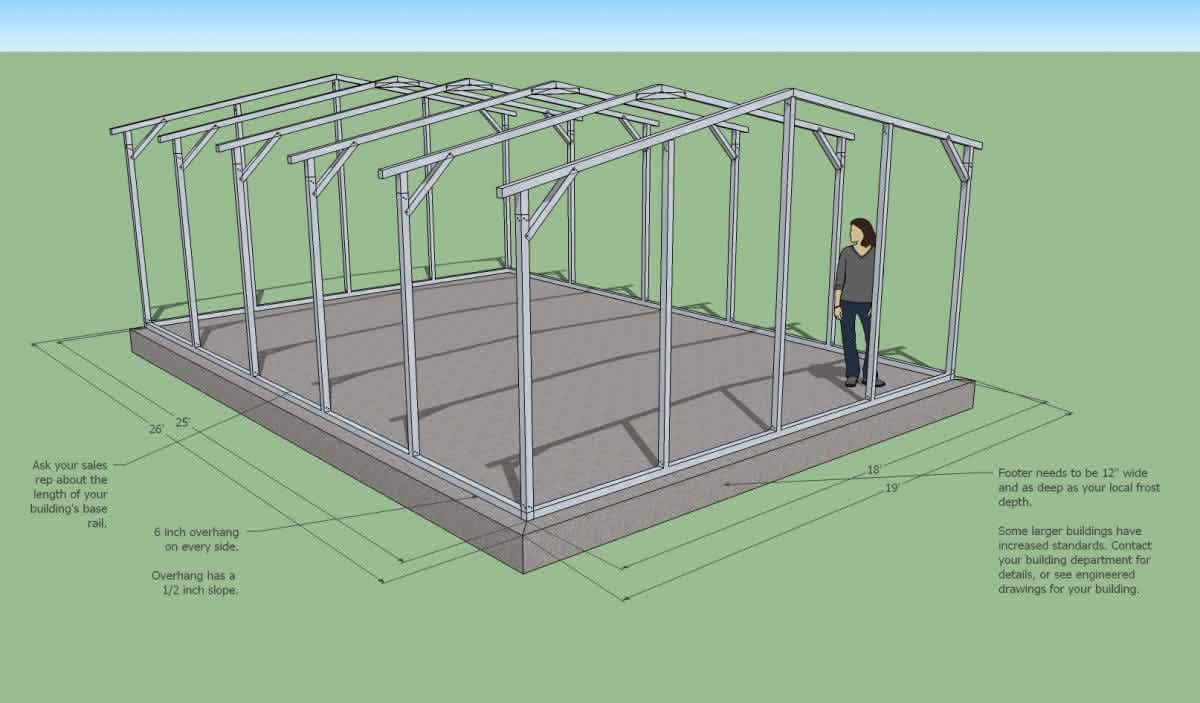

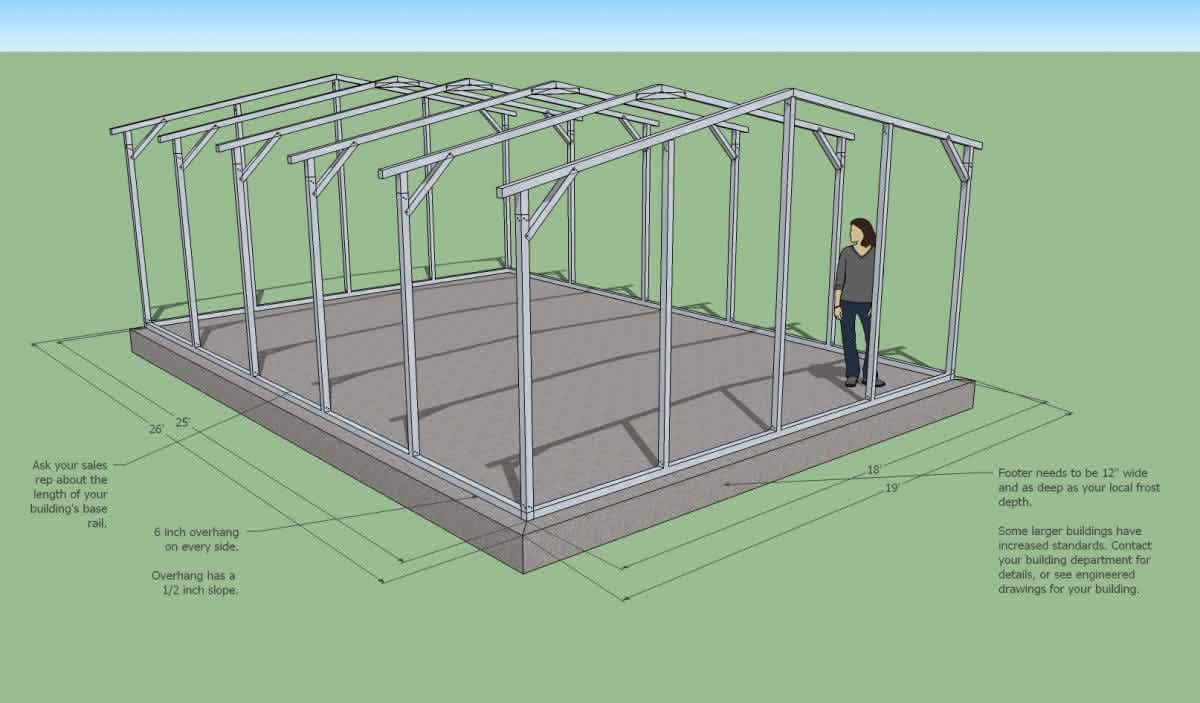

There are three main foundation options from which to choose. If your building is very large (like 40′ wide clear span), you will just have to go by drawings you purchased. The question: “How big do I need to make my slab?” is answered here as well.

!Pouring a Slab Foundation for a Carport or GarageEdge Offset Concrete Slab Foundation

- Edge Offset : The slab size is equal to the outside dimensions of the building PLUS 5″ in each direction.

!Pouring a Slab Foundation for a Carport or Garage Notched Edge Offset Concrete Slab Foundation

- Notched Edge Offset : The same as Edge Offset, but the extra 5″ is 1.5″ lower or "Notched."

!Pouring a Slab Foundation for a Carport or Garage Edge Flush Concrete Slab Foundation

- Edge Flush : The slab size is equal to the outside dimensions of the building.

The strongest slab option is the Edge offset, but it allows for water to flow under the bottom of your siding. The Edge Flush slab uses the least concrete; therefore is the cheapest and allows your siding to be installed, so it overhangs the foundation, thus preventing water from flowing under the walls. The Notched Edge Offset is probably the most expensive, but it is both strong like the edge offset style and allows the siding to set below the top of the slab. The notched edge offset style is our most recommended option. All three types of slabs will need a footer and a slab of at least 4″ thick. The footer's depth needs to be the frost line's depth or as per local code, but no less than 12″ deep. The width of the footer needs to be at least 12″ wide.

The Essential Considerations Before You Pour Foundations

Before you are ready to pour your carport slab, you must consider some specific considerations and how they will need to be mitigated for in the makeup of the slab materials you decide to use:

- Soil : before you get ready to pour, you will need to understand the type of soil in the area you are planning to build on. Consider whether it is high in clay content or whether the soil is so poor that it may shift or even sink, irrespective of how good the foundation is.

If the soil is poor, then you may want to consider bringing in better-quality soil for the area prior to pouring your carport concrete slab or metal building foundations. This will ensure that your building is installed safely and will last for many years without problems.

- Frost: knowing what the frost line is in your area is an essential part of knowing the answer to ‘how deep should footings be for a carport or metal building?'. The frost line is the depth to which the ground can freeze, and it will affect your foundation directly. However, it is different for each area, and so you will need to speak to your local building department to find out what it is in the area you want to install your building in.

- Weight : the other essential thing that you must know for your metal building or carport foundation requirements is how much the building will weigh. This weight includes the building itself and the contents that will be put inside the building when it is completed.

Anchoring

Some of our customers will want to know where to place their anchors. The engineered drawings best answer that question. If they do not have drawings, then a good rule of thumb is at each end AND next to every other support post. However, most building companies will offer their own anchoring. And some, like Coast to Coast Carports, add cement anchoring for free. They use self-tapping expansion anchors, wedge anchors, or adhesive anchors. Anchors need to be embedded at least 4″ into the slab and need to be placed no more than 6″ from support posts. All anchors need to be A307 equivalent or better.

Foundation Strength

The soil bearing capacity needs to be a minimum of 1500 psf. This means if you are placing it in a soft or squishy area or somewhere with a lot of sand, you may need to have to soil checked and, if needed, do additional foundation work to prep the soil. Your local courthouse will most likely be able to guide you through this process. Also, the concrete will need to be reinforced so that it has a minimum strength of 2500 psi at 28 days. Yes, this is the standard curing time for a foundation or slab. Some acceleration agents can be added to speed things up, however. Extra reinforcement should be in the form of a re-bar with wire or fiber mesh. If you do not need a permit and want to do your slab yourself, we suggest Googling "how to pour a slab for a garage myself." If you plan to purchase a steel building from Coast to Coast Carports, please call us with any additional questions at (866) 681-7846.

The Step-by-Step Process for Pouring Metal Building Foundation

When you are confident that you are ready to pour your concrete slab for metal garage, buildings, and sheds, then you can follow these steps to ensure that you do not go wrong or miss anything important out:

- Think about permits : in the US, each state has its own requirements for buildings, and local areas are responsible for issuing building permits when needed. Take the time to find out whether you need to apply for a permit before you start work. If you are not sure where to start, then head over to your local town offices to find out.

- Choose your site wisely : before you start preparing your site, take the time to choose the location sensibly. Remember that you will need to access your new building all year round, so always opt for an accessible and close area to other buildings if necessary.

- Preparation is key : clearing the area means removing all the plants, trees, shrubs, and debris that is currently taking up space where you want your metal building installed. It is also important to clear around the area so that the delivery crews and installers can access everything quickly and easily.

- Pick your foundation : once the site is ready for the pour, you will need to consider the best type of slab for your property and the area in which it is to be installed. If you need advice on this, then just get in touch, and we can discuss your options with you.

- Tell us about your site before delivery : the final stage in preparation for your new build, after you have completed your concrete slab for the carport and buildings is to tell us what you have chosen. The reason for this is so that our installers can bring the right anchors with them when the building arrives : saving you and them a lot of time.

Key Foundation Considerations

Finally, before you press ahead with your concrete slab for carport and metal buildings, you will need to have considered the following things:

- What carport slab thickness you need

- Does a garage slab need footings?

- What soil you have in your location?

- What weather your building will be exposed to

- How big is the building?

- The weight of your new building and the contents

If you need help to answer any of these questions or you want specific advice before proceeding, then do not hesitate to reach out to our team, who are ready and willing to help you with anything you need.

Why You Need to Choose Coast to Coast Carports for Your Metal Building Needs

When it comes to understanding the best ways to prepare your site and install your foundation, Coast to Coast Carports is here to help you in any way we can. We are the number one choice for customers across America and take great pride in manufacturing our metal buildings to the highest standards. Our mission to provide outstanding customer service. We offer free delivery and installation as well as a 20-year rust-through warranty so that you can be confident in the resilience of your new steel building. If you need a new metal building, then we are the right choice : call us today at ☎ (866) 681-7846 to meet your requirements.